Product Description

90 degree gearbox Low-noise CHINAMFG version gear box dc motor worm planetary motoreductor transmission auto parts machine gearbox

We have produced and exported the Motovario-like speed transmission gearbx for years,able to provide to all the customers with matureproducts in competitive prices and free technical support all the time.

Features

- Wide transmission rate, strong output torque

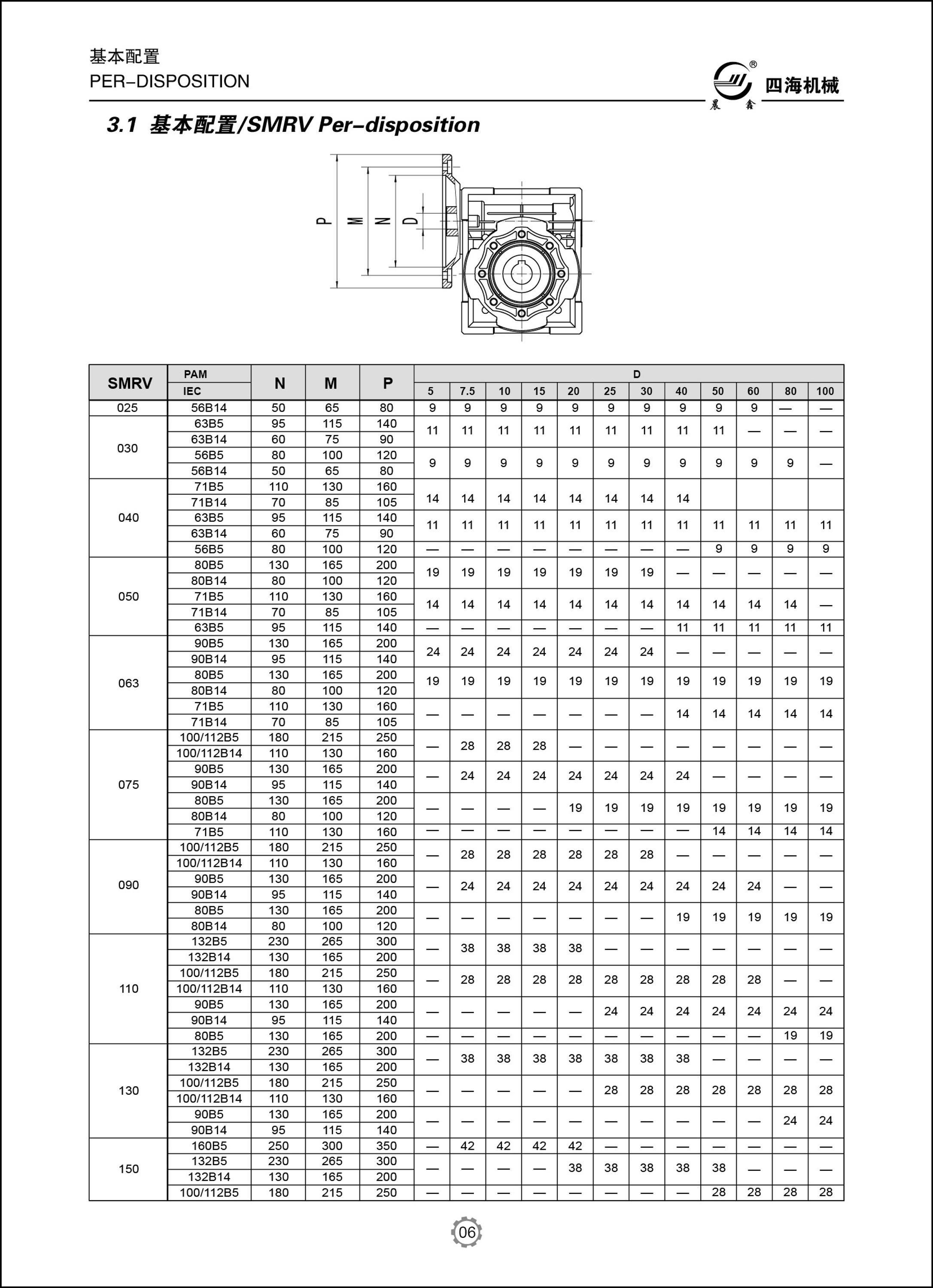

- Structure: base-mounted, input shaft, input flange, additional single or double output shafts

- Compact mechanical structure, light weight, small volume

- Good temperature change resistance

- Smooth operation with lower noise or vibration

- Easy mounting, free linking, high efficiency

- Wide range of application to the work flow devices,like conveyor belts,driven by motors or other engines,with requirements to slow the speed

Basic information

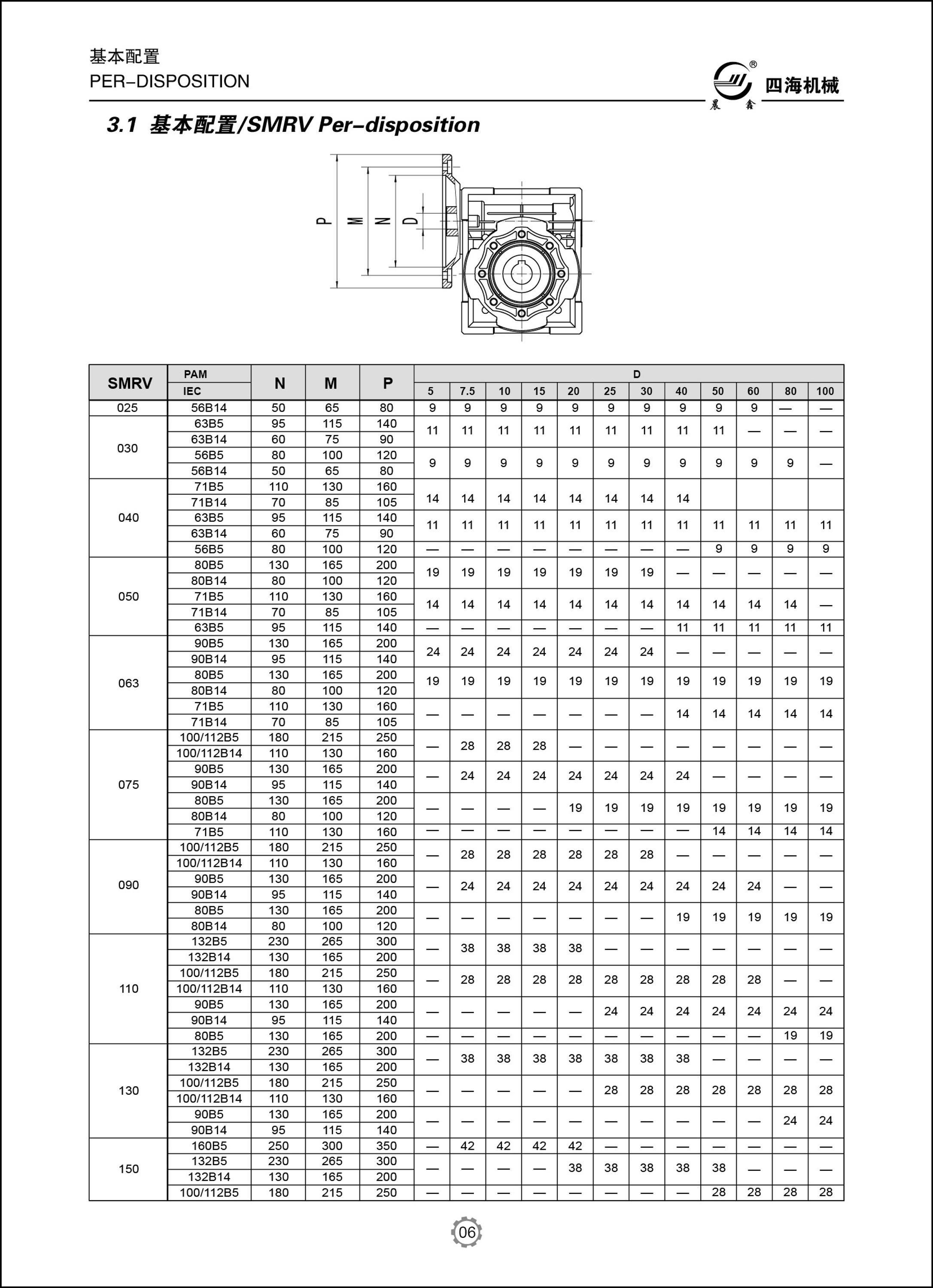

| Model | RV 130 150 |

| Single unit versions |

NMRV – fitted for motor flanged coupling, NRV – with input shaft, NMRV-E motor flanged coupling with worm extension shaft, NRV-E with double extension worm shaft,

|

| Series of products |

|

| Single unit reduction ratio | 1:5 7.5 80 100 |

| Output torque | 2.6—1195N.M |

| Power | 0.06—-15KW |

| After-sale service | Free components or complete units will be supplied to replace the damaged ones of quality problems during guarantee period,free technical support all the time. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Output Torque: | 2.6—23n.M |

| Output Speed: | 17.5-280rpm |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Can a Worm Gearbox be Used for High-Speed Applications?

Worm gearboxes are generally not recommended for high-speed applications due to their inherent design characteristics. Here’s why:

- Efficiency: Worm gearboxes tend to have lower efficiency compared to other gearbox types, which means they can generate more heat and experience more energy loss at high speeds.

- Heat Generation: The sliding contact between the worm and worm wheel in a worm gearbox can lead to significant friction and heat generation, especially at high speeds. This heat can cause thermal expansion, affecting the gearbox’s performance and longevity.

- Wear and Noise: High speeds can exacerbate wear and noise issues in worm gearboxes. Increased friction and wear can lead to faster degradation of components, resulting in reduced lifespan and increased maintenance needs.

- Backlash: Worm gearboxes may have higher backlash compared to other gearbox types, which can impact precision and accuracy in high-speed applications.

While worm gearboxes are more commonly used in applications requiring high torque and moderate speeds, they may not be the best choice for high-speed scenarios. If high-speed operation is a requirement, other gearbox types such as helical, spur, or planetary gearboxes are often better suited due to their higher efficiency, lower heat generation, and reduced wear at elevated speeds.

Worm Gearbox vs. Helical Gearbox: A Comparison

Worm gearboxes and helical gearboxes are two popular types of gear systems, each with its own set of advantages and disadvantages. Let’s compare them:

| Aspect | Worm Gearbox | Helical Gearbox |

| Efficiency | Lower efficiency due to sliding friction between the worm and worm wheel. | Higher efficiency due to rolling contact between helical gear teeth. |

| Torque Transmission | Excellent torque transmission and high reduction ratios achievable in a single stage. | Good torque transmission, but may require multiple stages for high reduction ratios. |

| Noise and Vibration | Generally higher noise and vibration levels due to sliding action. | Lower noise and vibration levels due to smoother rolling contact. |

| Backlash | Higher inherent backlash due to the design. | Lower backlash due to meshing of helical teeth. |

| Efficiency at Higher Speeds | Less suitable for high-speed applications due to efficiency loss. | More suitable for high-speed applications due to higher efficiency. |

| Overload Protection | Natural self-locking feature provides some overload protection. | May not have the same level of inherent overload protection. |

| Applications | Commonly used for applications requiring high reduction ratios, such as conveyor systems and heavy-duty machinery. | Widely used in various applications including automotive transmissions, industrial machinery, and more. |

Both worm and helical gearboxes have their place in engineering, and the choice between them depends on the specific requirements of the application. Worm gearboxes are preferred for applications with high reduction ratios, while helical gearboxes are chosen for their higher efficiency and smoother operation.

How to Select the Right Worm Gearbox for Your Application

Selecting the right worm gearbox for your application involves careful consideration of various factors:

- Load Requirements: Determine the torque and load requirements of your application to ensure the selected gearbox can handle the load without compromising performance.

- Speed Reduction: Calculate the required gear reduction ratio to achieve the desired output speed. Worm gearboxes are known for high reduction ratios.

- Efficiency: Consider the gearbox’s efficiency, as worm gearboxes typically have lower efficiency due to the sliding action. Evaluate whether the efficiency meets your application’s needs.

- Space Constraints: Assess the available space for the gearbox. Worm gearboxes have a compact design, making them suitable for applications with limited space.

- Mounting Options: Determine the mounting orientation and configuration that best suits your application.

- Operating Environment: Consider factors such as temperature, humidity, and exposure to contaminants. Choose a gearbox with appropriate seals and materials to withstand the environment.

- Backlash: Evaluate the acceptable level of backlash in your application. Worm gearboxes may exhibit more backlash compared to other gear types.

- Self-Locking: If self-locking capability is required, confirm that the selected gearbox can prevent reverse motion without the need for external braking mechanisms.

- Maintenance: Consider the maintenance requirements of the gearbox. Some worm gearboxes require periodic lubrication and maintenance to ensure proper functioning.

- Cost: Balance the features and performance of the gearbox with the overall cost to ensure it aligns with your budget.

Consult with gearbox manufacturers or experts to get recommendations tailored to your specific application. Testing and simulations can also help validate the suitability of a particular gearbox for your needs.

editor by CX 2024-03-30

China high quality excavator parts spare swing gearbox for CZPT SK135 SK135SR SK130-8 Hydraulic slew motor and reducer near me factory

Applicable Industries: Construction works , Energy & Mining

Showroom Location: None

Warranty: 1 Year, 6 Months-12months

After Warranty Service: Video technical support, Online support

Local Service Location: None

After-sales Service Provided: Video technical support, Online support

excavator swing motor: brand new

Application: Crawler Excavator

Part name: Swing Motor

MOQ: 1 Piece

Quality: High Guarantee

Condition: 100%new

Package: Wooden Case Packing

Packaging Details: standard export packing

Kobelco SK135 swing motor ,SK135SR SK130-8 Hydraulic slew motor and gearbox

Related Products

We can supply you all kinds of excavator spare parts as following:

Hydraulic Parts:

Hydraulic pump, Travel motor, Swing motor, Travel gearbox, Swing gearbox, Main control valve, Hydraulic cylinder assy, Gear pump, Pump regulator,etc.Undercarriage Parts:

Track link and shoe assy, Track roller, Carrier roller, Idler, Sprocket, Track link guide, Track Adjuster assy, etc.

Excavator Attachments:

Bucket ,mud bucket, High torque 220 volt 230v 10w ac shaded pole gear motor for Barbecue machine BBQ oven western kitchen fireplace equipment earth bucket, heavy duty rock bucket , skeleton bucket,hydraulic breaker, hydraulic quick coupler,ripper,etc.Cabin Parts:

Excavator cabin, Cabin door, Side door panel, Cabin seat, Cabin glass, Engine cover, Tool box, Door lock, etc.Electric Parts:

Controller, Monitor, Panel, Throttle motor, Solenoid valve, Wire harness, etc.Engine Parts:

Cylinder block, Cylinder head, Crankshaft, 3 4 6 Axis Machining Crankshaft for Motorcycle Racing Worm Gear Step Long Spindle Motor Eccentric Grinding Connecting CNC Shaft Engine assy, Injector, Fuel injection pump, Oil pump, Feed pump, Oil cooler, Filter, Turbocharger, Starter motor, Alternator, Water pump, Fan blade, Liner kits, Bearings, Valves, Gasket kit, etc.

Other Parts:

Seal kit, Floating seal, Joystick, Foot pedal valve, O-ring box, Coupling, etc.

Shipping methods

BY EXPRESS, Podshipnik 664916 D cylindrical roller radial roller bearing (needle bearing), without rings 81x92x42.5 mm for kamaz gearbox AIR, SEA

GOODS WILL BE SHIPPED WITHIN 3 DAYS AFTER PAYMENT RECEIVED.

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to change gear smoothly. This arrangement of gears is highly complex, which helps to provide a smooth gear change. In this article, we will explore some of the different types of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most common types of gearboxes used in automobiles.

Gearboxes

Gearboxes help drivers choose the appropriate gear for the conditions. A lower gear produces the least speed, while a higher gear gives the maximum torque. The number of gears used in a gearbox varies to meet different demands on the road and load. Short gearing provides maximum torque, while tall gearing offers higher top speeds. These features combine to improve the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of components, including the bearings and seals. Among these components is the gearbox, which is subjected to wear and tear due to metal-to-metal contact. As a result, gearboxes require close monitoring. Various tests are used to assess the condition of gears, such as corrosion and wear. Proactive tests emphasize wear, contamination, and oil condition. However, there are also proactive tests, such as the ferrous density test and the AN test, which monitor additive depletion and abnormal wear.

The separating force is a key factor for the design of a gearbox. The primary radial measurement point should be oriented to monitor normal forces. The secondary measurement point should be located in the opposite direction of rotation from the primary radial measurement point. The separating force generated by a helical gear set is called tangential force. The primary and secondary radial measurement points should be positioned so as to provide information about both normal and tangential forces.

Manual gearboxes are often manual. The driver can control the synchromesh by using a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh because they are used only when the vehicle is at a standstill. In older cars, the first gear often lacked synchromesh due to cost or lack of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox features high versatility and good combination. They have a wide range of motor power and allow for fine classification of transmission ratios. The R series gearbox has several advantages, including high efficiency, long service life, and low vibration. This series of gearbox can be combined with a wide range of reducers and variators. Its size and high performance makes it an ideal choice for applications that require maximum torque and load transfer.

The main feature of a helical gearbox is that it presents a fixed velocity ratio, even if the center gaps are not perfectly set. This is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to paper spur gears in terms of radial pitch, since the shafts in the helical gearbox cross at an angle. The center gap of a helical gearbox is the same for both the left and right-handed counterparts.

The EP Series is another popular model of a Coaxial helical gearbox. This series has high torque and a maximum reduction ratio of 25.6:1. It is an ideal choice for the plastic industry, and CZPT offers an extensive range of models. Their center distance ranges from 112 mm to 450 mm. The EP Series has several models with different center distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is easy to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a high efficiency and power density. Unlike coaxial helical gearboxes, planetary gearboxes have an axis on the same direction as the output shaft. They are easy to integrate into existing drive trains. In addition, they are compact and easy to integrate with existing drive trains. For servo applications, they are another great choice.

Epicyclic gearbox

An epicyclic gearbox is a type of automatic gearbox used to drive cars. Its primary advantage is its compact design, and it is more reliable and efficient than manual gearboxes. It is comprised of a sun gear and two planetary gears, encased in a ring gear called the Annulus. This system is useful for drivers who need to shift gears frequently, as they will become tired if the gears are suddenly changed.

An epicyclic gearbox consists of three different types of gears: ring gear, sun gear, and annular ring gear. The ring gear is the outermost gear and has angular-cut teeth on its inner surface. It is used in conjunction with planetary gears to provide high-speed ratios to vehicles. The sun gear also reverses the direction of the output shaft. This helps reduce transmission error.

An epicyclic gearbox uses multiple planets to transfer power between the planets. This type of gearbox is lightweight and features a high power density. This gearbox has several benefits over a standard single-stage parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. Furthermore, epicyclic gearboxes require more complex transmission error optimisation than their counterparts, including more than one stage.

The objective of epicyclic gearbox research is to provide the lowest transmission error possible. The process includes an initial design and detailed specification. The system is defined by its load spectrum and required ratio. Deflections of the elastic mesh are calculated to understand their strength and how much energy the system can handle. Finally, micro-geometric corrections minimize transmission error. These improvements are crucial to the overall efficiency of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is fixed at an angle, enabling more interaction with the shaft in the same direction as it moves. As a result, the shaft and the bearing are in constant contact for a long period of time. Typically, extruder helical gearing is used in applications where there is low excitement, such as steel, rolling mills, conveyors, and the oil industry. The bevel gear train also plays a role in these applications.

The CZPT AEX extruder drive gear is specifically developed for this specific application. The gears are compact and lightweight and offer exceptional power density and a long service life. These extruder gears are highly reliable, and they can be used in a wide range of applications, including rubber processing, food production, and recycling plants. CZPT offers both standard and custom gearing for your extruder.

Another advantage of helical gearing is its versatility. Since the helical gearing teeth are inclined at a specific angle, they can be adjusted to meet the specific needs of a given application. These gears also have the advantage of eliminating noise and shock from straight teeth. Unlike other gearing types, they are able to achieve a wide range of loads, from small to large. These helical gears are very durable and are the best option for high-load applications.

In addition to this, asymmetric helical gears have increased flexibility, while asymmetrical helical gears have lower flexural stiffness. The ratio of teeth to the shaft has a positive effect on the strength of the gear. Furthermore, asymmetrical helical gears are easier to manufacture. But before you purchase your next extruder gear, make sure you know what you’re getting into.

1 speed gearbox

CZPT Group Components produces the one speed gearbox. It has the potential to make cars more efficient and environmentally friendly. The gear ratio of a car’s drivetrain is crucial for reaching maximum power and speed. Typically, a one-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can reach this power must be high to get the full benefit from the electric motor. So, how can a one-speed gearbox improve the speed and torque of a car?

A one-speed gearbox is a mechanical device used to switch between second and third gears. It can include multiple gear sets, such as a shared middle gear for switching between second and third gears. It can also have an intermediate gear set that represents a switchable gear in both partial transmissions. The invention also includes a mechanism that makes it easier to change gears. The patent claims are detailed below. A typical one-speed gearbox may include two parts.

Generally, a one-speed gearbox will have up to seven forward gears, with each of these corresponding to a different speed. A one-speed gearbox can have five different gear sets and five different gear levels. It can have synchronized gear sets or last-shelf gear sets. In either case, the gears are arranged in a way that maximizes their efficiency. If the gears are placed on opposite sides of a car, the transmission may be a two-speed one.

CZPT Transmission specializes in the production of high-speed gearboxes. The company’s Milltronics HBM110XT gearbox machine is the perfect tool for this job. This machine has a large working table and a heavy-duty load capacity, making it a versatile option for many kinds of applications. There are also a wide variety of CZPT gearboxes for the automotive industry.

in Vancouver Canada sales price shop near me near me shop factory supplier Adjustable Motor Slide Base bed base motorsbase de motormotorized para motorbase para de automovilplaca delantero transmission parts motor base manufacturer best Cost Custom Cheap wholesaler

Moreover, WE CAN Generate Custom-made VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Merchandise In accordance TO CUSTOMERS’ DRAWINGS. We are looking forward to building effective company associations with new consumers around the entire world in the long term. Maintaining in thoughts that good service is the key to cooperating with customers, we try to fulfill higher top quality standards, offer aggressive costs and guarantee prompt supply.

Adjustable EPT Slide Base mattress foundation motorsbase de motormotorized para motorbase para de automovilplaca delantero EPT areas motor base

At any time-EPT EPTist in making all varieties of mechanical EPT and EPT EPT like: planetary EPTes, worm EPTs, in-line helical EPT velocity EPTs, pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel shaft helical EPT EPTs, helical EPTl EPTs, helical worm EPT EPTs, agricultural EPTes, tractor EPTes, automobile EPTes, pto EPT shafts, EPT EPT amp associated EPT components and other relevant goods, sprockets, EPT system, vaccum pumps, fluid coupling, EPT racks, EPTs, timing pulleys, udl speed variators, v pulleys, EPT cylinder, EPT pumps, screw air compressors, shaft collars minimal backlash worm EPTs and so on. in addition, we can make tailored variators, EPTed motors, electrical motors and other EPT products in accordance to customers’ drawings.

The company gives a reliable gurantee for the product’ s top quality by EPT inspection and tests gear. specialist specialized crew, beautiful processing EPT and stringent handle system.

In modern a long time, EPT has been deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ing rapidly by its wealthy knowledge in creation, adcanced managemant program, stXiHu (West Lake) Dis.Hu (West Lake) Dis.rdized administration technique, sturdy technical power. We alwaEPTadhere the notion of survial by good quality, and deceXiHu (West Lake) Dis.Hu (West Lake) Dis.ment by innovation in EPT and EPT.

At any time-EPT Group is ready to function with you hand in hand and EPT brilliance together!

Aluminum near me shop made in China – replacement parts – in Nanded Waghala India Washing Parts Die Casting Motor Pulley Brake Wheel Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| Description | Aluminum Die Casting |

| Application | Heat dissipation |

| Material | ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100, zinc alloy, etc. |

| Hardness | 8-12HW |

| Heat treatment | T3-T8 |

| Surface Treatment | Clear anodizing, Black anodizing,powder coating,brushing; sand blasting; shot blasting;polishing |

| Customized designs | Yes, we can. |

| Deep process | Cutting, milling, drilling, punching, CNC ect |

| Free Samples | Yes, we can. |

| Packing | Carton, wooden pallet or by your request. |

| Payment | T/T, L/C |

| Logistics | HangZhou, Express |

| Shipment Time | 1 week to 3 weeks |

Drawing→ Mold → Die casting → Deburring → Drilling holes → Tapping → CNC Machining → CNC control center → Polishing → Surface Finishing → Assembly → Quality Inspection → Packing

Factory Pictures:

1. EPT and professional service:

We have a high quality sales team including sales staff , quality engineers and technicians .

2.Quality control:

The passing rate of finished product is more than 99% . Every product need to be checked by many processes.

3.Comprehensive service:

Delivery will be ready within 30 days after receiving your down payment .

We have been in this field for 20 years, covering ovearseas market of 30 different countries .

EPT all the products with good quality and competitive price .

4.Long term win-win cooperation:

A reliable supplier and reputable supplier is the key to your business. EPT mu EPT be the be EPT choice for you!

Q1: What is your MOQ for die casting?

A1: Our MOQ is 100 pieces.

Q2:Do you offer free sample for die casting?

A2: We can provide you a sample but you need to pay for it and also the freight .

Q3: What is your payment term for die casting?

A3: 30% down payment after confirming the contract/PI and the balance before shipment/copy of Bill of Lading .

Q4: What normal cooperation processes do you have?

Fir EPT , we need your drawing for quotation .

Second , you accept our quotation , then you pay for the tooling co EPT and we will arrange to make the sample on approval .

Third , you approve with the sample and we make sales contract for you to confirm .

Fourth , manufacturing products and shipping to you .

Fifth , you pay us the balance .

Finally , you receive ca EPT aluminum parts and feedback .

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Factory made in China – replacement parts – slat band chain conveyor in Tegucigalpa Honduras Price Roller Chain Conveyor with Motor with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox factory in China with 5 different branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

The team has taken part in the generating and revising of ISO/TC100 global chain regular many several years in success and hosted the sixteenth ISO/TC100 Intercontinental yearly assembly in 2004. Our we source chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes and so forth. capabilities go far beyond the scope of our catalog. Based mostly on customer demand, we now stock solid collars with oversized bores for apps in which the common tolerance does not allow for ample clearance. We also supply numerous finishes for solid and break up collar like yellow zinc, nickel and chrome. Many are even stocked for off-the-shelf supply. We also manufacture and inventory sound collars with 2 established screws, with through holes, and with out holes. Collars are available in inch and metric measurements. Heavy collection clamp-type collars and threaded collars are also available. We can even provide sq. bore collars for quantity specifications. And if your specific specifications repeat regularly, we are glad to stock components for scheduled releases. Whatever your collar needs, Lucas Industrial is your provider for substantial quality cost – efficient factors. EPG is a foremost supplier of substantial good quality, price-powerful energy transmission parts. As our item strains proceed to expand to meet our customer’s needs, our commitment to personalised client services and on-time delivery continues to be second to none.

Substantial top quality china supplier pvc belt conveyor roller

• fifty-800kg/h potential.

• Adjustable conveyor height and velocity.

• 195-1000mm conveyor width.

• Offered in any duration to suit your programs.

• Self Monitoring: Cartons comply with the twists and turns of the conveyor path with no utilizing engineered curves.

• Adjustable Top: Basically switch the locking knob to increase and reduced the conveyor mattress peak.

• Aspect Plates: Aluminum alloy construction attributes a ribbed layout for extra longevity. Assembled with bolts and lock nuts.

| Product Name | Automated Roller Conveyor For Cartons |

| Content | Stainless/Metal/Carbon Steel/Galvanized Steel |

| Pitch | As your application |

| Certification | ISO&CE&SGS |

| Processing | Injection molding and machining |

| Structure | Height/Speed adjustable |

| Color | As requirement |

| Software | Food & beverage &Packing industry & Pharmacetic etc |

Our organization

Packing & Delivery

FAQ:

Q1:Are you manufacturing facility or investing organization?

A: We are manufacturing unit and manufacturer.

Q2: The place is your manufacturing facility situated? How can I visit your factory?

A: We are found in HangZhou. It is about 4 hours to achieve HangZhou or ZheJiang port from our manufacturing facility in China.

Q3:How to place my buy?

A: Ju EPT make contact with us via Trade Manager, E-mail, Skype or telephone to verify the devices, generating the deposit then we will start generation.

Q4 : What is the payment term?

A: 50% TT in progress, fifty% TT just before supply soon after production

Q5:How extended is the creation time?

A: About 10 doing work times.

Q6: Fir EPT time import, how can I believe that you would send merchandise ?

A: We are confirmed firm by produced-in-China.com to make transaction successful.

Q7: How to make certain that I received the equipment undamaged?

A: To start with, our package deal is stHangZhourd for cargo, we mu EPT validate devices undamaged prior to supply, and we’ve acquired insurance coverage for you, we will take the duty if devices destroyed.

Q8: What soon after-product sales support or any concern about items?

A: All machines enjoy 2 years guarantee , you can get in touch with me by mail if any difficulties, I will reply you as soon as feasible.

Contact data

The use of unique equipment manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our firm and the outlined alternative components contained herein are not sponsored, authorized, or manufactured by the OEM.

Best China manufacturer & factory RV reductor motor gearbox spare parts and worm speed reducers With high quality best price

Our products are applied in many fields.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining

- Gearing Arrangement:

-

worm

- Output Torque:

-

2.6-1195N.M

- Input Speed:

-

1400r/m

The PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HP

- Output Speed:

-

14-280rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

NMRV025-NMRV150

- Rated Power:

-

0.06kw-15kw

- Material:

-

Aluminium

- Color:

-

Blue

- Input flange:

-

56B14/71B5/80B5..

- Bearing:

-

NSK bearing/homemade bearing

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- 1 set / carton,several cartons / wooden pallet

- Port

- Shanghai / Ningbo

Online Customization

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

Characteristics:

(1)Large output torque

(2) Safe, reliable, economical and durable

(3) Stable transmission, quiet operation

(4) High heat-radiating efficiency, high carrying ability

(5) Combination of two single-step worm gear speed reducers, meeting the requirements of super speed ratio

(6) Mechanical gearboxes are widely used in the sectors,like foodstuff, ceramics, and chemical manufacturing, as well as packing, printing, dyeing and plastics

Technical data:

(1) Motor input power:0.06kw-15kw

(2) Output torque:4-2320N.M

(3) Speed ratio of worm gear peed reducer: 5/10/15/20/25/30/40/50/60/80/100

(4) With IEC motor input flange: 56B14/71B14/80B5/90B5…

Materials:

(1) NMRV025-NMRV090: Aluminium alloy housing

(2) NMRV110-150: Cast iron housing

(3) Bearing: NSK bearing & Homemade bearing

(4) Lubricant: Synthetic & Mineral

(5) The material of the worm mandrel is HT250, and the worm ring gear is Zepgn10-1.

(6) WitWithout adequate venting, high temperatures increase internal pressure which can force lubricant past seal lips or increase lip contact pressure, accelerating seal wear and grooving on the seal journals.h high quality homemade bearings, assembled NAK oil seals & filled with high quality lubricant.

Operation&mantenance

(1)When worm speed reducer starts to work up to200-400 hours, its lubricant should be replaced.

(2)The gearbox need to replace the oil after 4000 hours.

(3)Worm reduction gearbox is fully filled with lubricant oil after finshed assembly.

(4)Lubricanting oil should be kept enough in the casing and checked at a fixed time.

Color:

(1) Blue / Light blue

(2) Silvery White

Quality control

(1) Quality guarantee: 1 year

(2) Certificate of quality: ISO9001:2000

(3) Every product must be tested before sending